The Great Motor Hunt: Finding Your FPV Drone’s Perfect Match

Embarking on the journey to find the ideal FPV drone motors can feel like navigating a complex maze. With numerous options available, it’s essential to understand the key factors that influence your decision. In this guide, we’ll explore the world of FPV drone motors, providing you with the knowledge to make an informed choice.

Motor Basics: Unlocking the Secrets of Propulsion

What Makes a Motor Tick?

At the heart of every FPV drone lies its motors, the powerhouse responsible for propelling your drone through the skies. These motors convert electrical energy into mechanical energy, generating the thrust needed for flight. Understanding the basics of motor construction and terminology is crucial in making an informed decision.

Key Motor Specifications

- KV Rating: This indicates the motor’s RPM (revolutions per minute) per volt. Higher KV ratings mean faster speeds, while lower KV ratings provide more torque.

- Stator Size: The stator is the stationary part of the motor, and its size affects the motor’s power and efficiency. Common sizes include 1306, 1806, and 2204.

- Magnet Type: Motors use either N50 or N52 magnets, with N52 offering stronger magnetic properties and improved performance.

Matching Motors to Your Drone: A Delicate Balance

Drone Size and Weight Matters

The size and weight of your drone play a significant role in motor selection. Larger drones require more powerful motors to achieve efficient flight, while smaller drones benefit from lighter, more agile motors. Consider your drone’s dimensions and weight when choosing motors to ensure a perfect match.

Flight Style and Performance

Your flying style and desired performance are crucial factors. Are you a freestyle pilot seeking agility and responsiveness, or a racing enthusiast prioritizing speed and acceleration? Different motors cater to various flight styles, so choose accordingly.

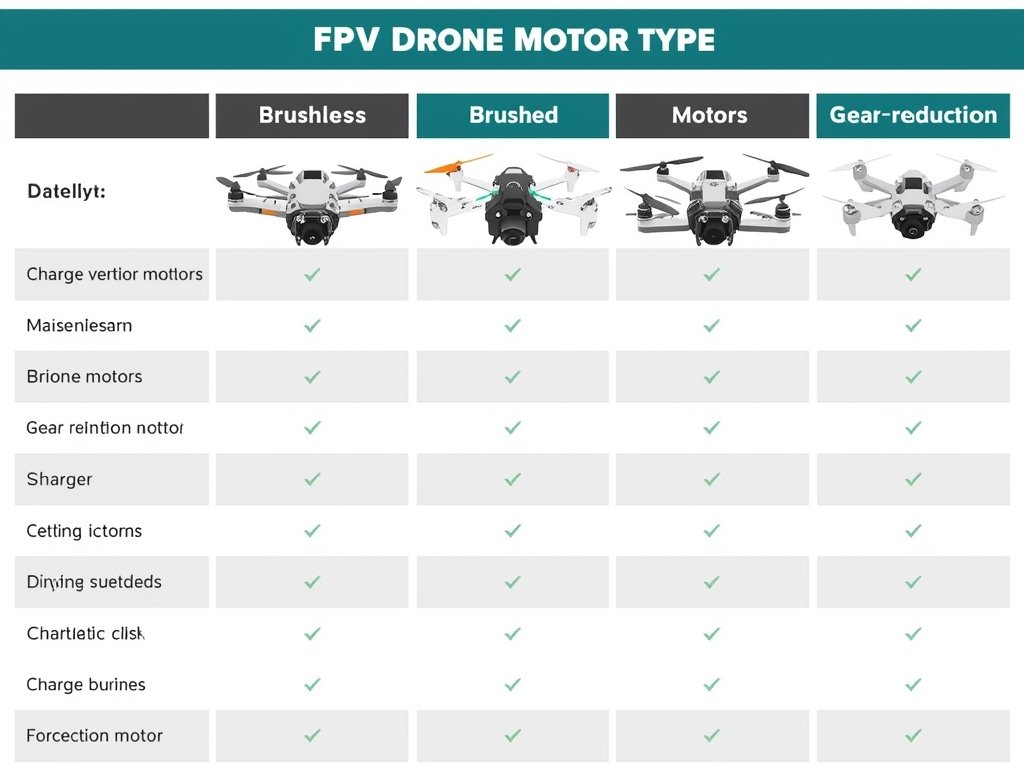

Motor Types: Navigating the Options

Brushless Motors: The Industry Standard

Brushless motors dominate the FPV drone market due to their efficiency, power, and durability. They offer a wide range of KV ratings and stator sizes, making them suitable for various drone setups. Brushless motors are ideal for pilots seeking high performance and reliability.

Brushed Motors: A Budget-Friendly Alternative

Brushed motors are a more affordable option, commonly found in smaller drones and beginner setups. While they may not match the performance of brushless motors, they are easy to use and maintain. Brushed motors are perfect for those on a budget or new to the hobby.

Gear Reduction Motors: Precision and Control

Gear reduction motors provide precise control and are often used in cinematic drones or applications requiring slow, stable movements. These motors offer a unique flying experience, prioritizing smoothness over speed. Consider gear reduction motors if you value precision and control.

Brand Spotlight: Top Motor Manufacturers

The FPV drone motor market is filled with reputable brands, each offering unique products. Here are some top manufacturers to consider:

- T-Motor: Renowned for their high-quality, efficient motors, T-Motor offers a wide range of options for various drone setups.

- Emax: Emax provides affordable, reliable motors without compromising performance, making them a popular choice among enthusiasts.

- Cobra: Cobra motors are known for their power and durability, catering to pilots seeking high-performance solutions.

Maintenance and Care: Extending Motor Lifespan

Keeping Your Motors in Top Shape

Proper maintenance is essential to ensure your motors perform optimally and last longer. Regular cleaning, inspection, and lubrication can prevent premature wear and tear. Develop a maintenance routine to keep your motors running smoothly.

Common Motor Issues and Troubleshooting

Motors can encounter issues like overheating, bearing wear, or magnet damage. Familiarize yourself with common problems and their solutions to address them promptly. Regular maintenance and timely repairs will keep your motors in excellent condition.

FAQ: Answering Your Burning Questions

What’s the ideal KV rating for a beginner FPV drone?

For beginners, a KV rating between 1900 and 2300 is a great starting point. This range offers a balance between speed and control, allowing new pilots to develop their skills without being overwhelmed by excessive power.

How do I choose the right stator size for my drone?

Stator size selection depends on your drone’s weight and desired performance. As a general guideline, smaller drones (under 250g) pair well with 1306 or 1806 stators, while larger drones benefit from 2204 or bigger stators. Consider your drone’s specifications and flying style when choosing the stator size.

Are brushless motors worth the investment?

Absolutely! Brushless motors offer superior performance, efficiency, and durability compared to brushed motors. While they may come at a higher cost, their long-term benefits and improved flying experience make them a worthwhile investment for serious FPV drone enthusiasts.

How often should I clean and maintain my motors?

Regular maintenance is key to extending your motors’ lifespan. Aim to clean and inspect your motors after every 10-15 flights or at least once a month, depending on usage. Develop a maintenance routine that includes cleaning, lubrication, and bearing checks to keep your motors in top condition.

Can I use gear reduction motors for racing?

While gear reduction motors provide precise control, they are not typically used for racing due to their slower speed and reduced agility. Racing drones prioritize speed and responsiveness, making brushless motors with higher KV ratings more suitable for competitive racing environments.

Your definitive resource for drone technology. From expert reviews of the latest DJI models to professional Part 107 flight training and industry regulations